Introduction-

Eddy Current Testing(ECT) is one of part of Non- Destructive or NDT methods, used to detect flaws or discontinuity in Conducted materials using Eddy Current.

These terms may be strange to you, If do, Then, Don’t worry, I will start from scratch, So, you never have to confuse about terms and before going you have cleared the concept regarding the eddy current test as well.

So, Seat back and relax and let’s start the journey of Eddy current inspection in front of you and at your fingertip.

Before, Moving to the title of the article, there is some basic information, which you need to know to get understood properly like- What is eddy current and How does it work. This will further help you know When these terms will arise further in this article.

So, Let’s Get started…

What is Eddy Current?

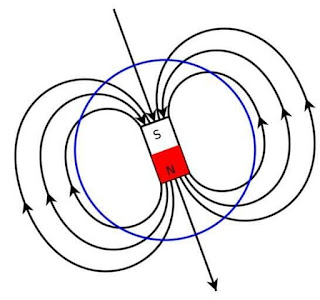

It is the induced current in a conducting body due to a change in magnetic flux and that induced current is called Eddy Current.

It is basically a loop of Circular Current like eddies in the water, formed by the induced magnetic field to conductor material.

How does It Work?

When a current is induced in the solenoid coil, it generates changing magnetic field or Magnetic Flux in it.

When we place any conducting metals between the field lines and Induce a magnetic field generated in conducting material. Due to electromagnetic force, Eddy forms in Conducting material in a circulating manner like a whirlpool in the river or sea.

That was some key definition and working, Which you read above, will help you to understand more clearly. Now, I am going to head on to the main topic of the article.

Are you ready?

Then, Let’s get started from basic and, we will both move to advance little by little in a digestible manner.

First of all, I will start with the Definition of Eddy current inspection in NDT, Principle and its working and more on down the road. So, stay with me and scroll gently and slowly.

What is Eddy Current Testing?–

A method of Non-Destructive testing, where a conducting material is inspected by the help of Eddy Current, Known as Eddy Current testing.

Principle of Eddy Current Testing-

ECT works on the principle of Electro-Magnetic Induction.

You may ask, What the heck electromagnetic induction is, Then don’t worry and stay with me.

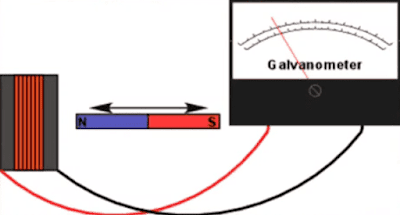

Electro-Magnetic Induction– when we place a magnet near the conductive coil, Current is induced to the coil and that current can be seen on Galvanometer, But the condition is that that magnet should be in changing direction. This is called electromagnetic Induction.

In short, Changing magnetic field can induce a current in conductive material or coil, Known as electromagnetic induction.

This law is introduced by Michel Faraday.

This was the principle of ECT. Now, I am moving to how does ECT works and the procedure of ECT.

I hope, You gaining knowledge and clearing your concept through this extensive guide. If so, Then stay with me and move your finger slowly, because more is to come on the road. So, why miss?

Isn’t?

How does Eddy Current Testing Works?

You know how eddy current is formed in conductive material and you also know that every current generates the magnetic field lines in its path.

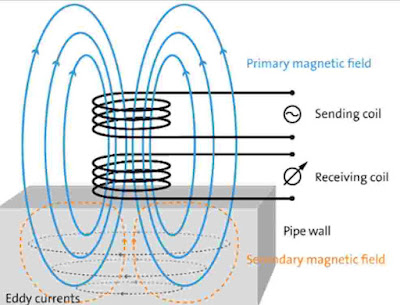

In ECT testing, both magnetic fields(ie. primary magnetic field and Secondary magnetic field) oppose each other, formation distortion in current or changing current.

When any discontinuity arrives in the conductive test piece, Distortion happens in the eddy current, due to distortion in eddy current, same happens in its magnetic field.

That distorted magnetic field cause to make distortion in the primary magnetic field and hence the primary current, that distorted current can be seen on display.

Here is the Diagram, Have a look-

✹Diagram of Eddy current testing-

Procedure-

The various procedure is followed, when Eddy current inspection is done. Have a look at these steps-

Induction of Current–

A probe carrying a primary magnetic field, taken to near the surface of a conductive test piece, due to the primary magnetic field, Secondary magnetic field induced in the test piece and hence form an eddy current in the test material.

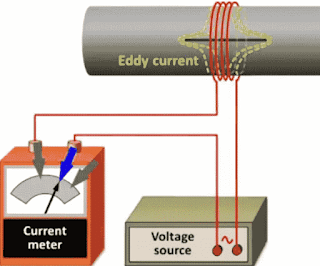

Detection of Discontinuity-

When current is induced in the test specimen, fluctuation of current can be seen in the current meter, if any discontinuity is encountered in the test specimen due to a change-in eddy current. See the picture below.

Identification-

When the change in current is encountered on the display, this indicates any discontinuity or flaw in the specimen. Then location is marked and sent to repair If needed.

Equipment used –

Basically, two eddy current testing equipment is used –

1. Straight or Angled Probe

2. Analog or Digital Meter

1. Straight or Angled Probe-

Probes are used to insert a magnetic field in the conductive materials and hence measuring the change in eddy current. Probes can be straight or angled, according to inspection condition or structure of test material.

2. Analog or Digital Meter-

A display is used to see the change in current and hence the location of the discontinuity. The display can be analog or digital.

Types of Probes-

Two types of test probes are used in Eddy current testing-

1. Absolute probes

2. Differential probes

1. Absolute Probes–

Absolute probes are single coil probes used to sense changes in magnetic field or change in eddy current. It is also known as Single-ended probes.

Absolute probes are used to measure conductivity and discontinuity in general.

Some of the absolute probes are- Surface probe, Encircling Probe, Bobbin probe.

Differential probes are those, that have two active coils calibrated in the opposite directions of each other to measure differential signals of two points at the same time of changing in the magnetic field or eddy current of the conductive test material.

Basically, Differential probes are removed the common noise between those two points and show the common results between the two points.

Differential probes are highly sensitive in terms of detection.

Fig. Eddy current testing machine and probe-

Testing Frequencies–

Here are frequency and its factors consider during the test-

- The frequency of alternating current inspection is 100HZ to 4MHz.

- Higher frequencies are suitable for detecting surface and sub-surface defects.

- Lower frequencies are suitable for detecting deeper defects.

- Frequencies can vary depending on the testing factors.

Now, I am moving into the advantages, disadvantages, limitations and applications of Eddy current inspection.

So, here we go…

Advantages of Eddy current testing-

The various advantages of ECT, Given below-

- Fast inspection

- Minimum part surface preparation

- Detect surface and near-surface defects

- Instant result

- Can be automated

Disadvantages-

The various Disadvantages of ECT, Given below-

- The surface must be accessible to the probe

- Surface finish and roughness may interfere in the test result

- Flaws such as delaminations that lie parallel to the probe coil winding and probe scan direction are undetectable

Limitations-

The various Limitations of ECT, Given below-

- Only conductive materials can be inspected

- Skill and training required to be more extensive than other techniques

- Reference standards needed to setup

- Depth of penetration is limited

Applications-

The various Applications of ECT, Given below-

- Measure coating thickness

- To identify electrical conductivity

- Magnetic permeability

- Grain size measurement

- Heat treatment condition

- Hardness

- Physical dimensions

- Automotive industry

- Aircraft Manufacturing

I hope, you enjoy reading. If so, more are coming to you, Stay with

me.

Now, here are some specific testing done through ECT. Given below, Have a look-

Eddy current testing of Tubes–

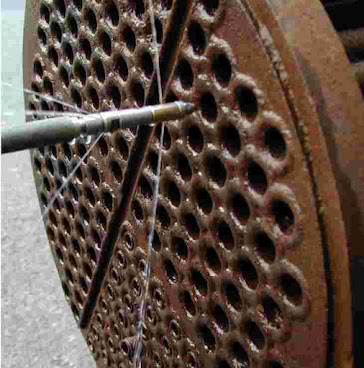

Ect is used to test tubes in effective ways, Where a probe is inserted in the tube hole to the desired length and hence results can be observed on the display or monitor.

various flaws like corrosion, cracks, pitting and so on, can be easily detectable through this technique.

Tube testing is basically performed in the boiler, chemical industries, gas pipelines, air conditioning lines, etc.

More on eddy current testing of tube

Eddy current testing of Heat Exchanger tube–

Heat exchanger tubes are being used to regulate the temperature of fluids. where the Circumferecial structure of tubes is very difficult to detect.

That’s why ECT is the best method to inspect heat exchanger tubes, Where Absolute probes are inserted to the desired length and seen any variation in current on the display.

Shown in fig-

Eddy current testing of Chiller tubes-

Chiller tubes are basically used in various mechanical industries, Where the cooling agent is pumped into the chiller tubes caused to cool out the outer liquid.

As I mentioned, eddy current inspection is a widely used method to inspect tubes and hence chiller tubes are inspected through the same process as we go through the testing processes of other tubes.

It is a pretty fast method to inspect tubes, once the initial setup is done.

Shown in fig-

Eddy current testing of condenser tubes–

The condenser is used to condense gaseous substances into liquid form using the cooling agent. Condensers are also used as heat rejection appliances in various mechanical and chemical industries.

As far as testing of condenser tubes is concerned, This also tested as same technique as other tubes through ECT.

The absolute probe is inserted to the end length of the tube and reading is seen on the display.

Eddy current testing for Hardness Testing-

Hardness testing is done to measure the resistance of the material by using more hard material among the test material.

Eddy current inspection is used to inspect the causes of failure in hardness testing.

Basically, ECT is used to identify, what types of flaws forms and lead to failure in the hardness testing.

Further, it helps to restructure materials and strengthening them ahead.

More on How to use eddy current for hardness testing

Eddy current Array-

Eddy current array is the modified version of Eddy current testing, Where series of the coil is used to detect the flaws.

The coil is activated in the sequence to remove the inference between coils.

The series of coils offers a wide range of coverage and even helps to identify circumferential discontinuity without rotating the probe unlike eddy current inspection and hence saves much time.

This video guide will help you to get more clarity about the eddy current array inspection of carbon steel. Give a watch-

The magnitude of induced eddy current depends on the following factors–

- The magnitude and frequency of the current flowing in the coil.

- The electrical conductivity of the specimen.

- The magnetic permeability of the specimen.

- The shape of the specimen.

- The relative positions of the coil and specimen.

- The microstructure and hardness of the specimen.

- The amount and types of defects in the specimen.

Codes and Standards of Eddy current testing–

ASTM-E2884-17– Standard guide for eddy current testing of Electrically conducting materials using conformable sensor arrays. (Resource- ASTM) ISO 15548-1 – Equipment for eddy current testing.

ISO 15549 – General principle of eddy current testing

ISO 20339– Array probe characteristics and verification of equipment for eddy current testing. (Resource- ISO)

Conclusion-

Eddy current testing is the widely used and hassle-free testing method. As you gain knowledge about the same in the detailed manner above.

If you are still there and reading this, Hit a share button and share to world out to spread knowledge to the needed one.

Thank you for being with me, bookmark to get the best knowledge about mechanicals and testings.

Hope to see you soon.

Before you go, Here are your freebies all yours-

| Eddy current testing ppt |  |

| Eddy current testing pdf |  |

FAQs-

Q. Can eddy current detect cracks?

Ans. Yes, ECT can detect cracks.

Q. Why is it called eddy current?

Ans. The path of the current is formed like eddies, That’s why it is called eddy current.

Q. Does Eddy Current give shock?

Ans. No, it doesn’t give shock due to the very small amount of voltage difference.

Abhishek Tiwary is a blogger by passion and a Quality Engineer by profession. He completed his B.Tech degree in the year 2017. Now working in a reputed firm. He loves to share his knowledge with others.