Introduction-

today I am going to discuss the Lancashire boiler, from scratch to end.

If you are here to know this fire tube boiler, then you are on the right path, so stay here and let me drive you to this knowledgeable journey.

So, without wasting your time, let me start the journey with you at Engineers Rail.

Before I start, It would be nice to have the Lancashire boiler pdf and Lancashire boiler ppt with you for further need. Hence, you can download this whole article in these formats at the end of the article.

So, Here we go…

Lancashire Boiler-

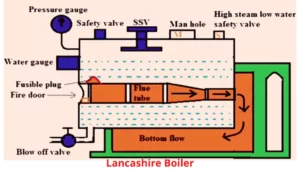

Lancashire Boiler is a low-pressure, internally fired, stationary fire tube boiler with natural circulation with a maximum pressure range of 16 bar.

The steam production rate of this boiler is 9000kg/hr and efficiency is 50% to 70%. Here the working principle of the Lancashire boiler is heat exchange.

Parts of Lancashire Boiler-

Here are some major parts with the uses and construction of this boiler-

- Boiler shell

- Grate

- Fire Box

- Water level indicator

- Safety valve

- Fusible plug

- Steam stop valve

- Manhole

- Low water safety valve

- Fire Bridge

- Blow off cock

- Economiser

- Damper

Boiler shell–

The cylindrical Boiler shell consists of two fire tubes surrounded by water. this boiler shell has a diameter of 2m, where the length can be from 8 to 10m.

Grate–

The grate is used to burn the solid fuel inside the firebox in the boiler shell because this is an internally fired boiler.

Fire Box–

Firebox consists of the grate and other firing equipment and this firebox is used to put the solid fuel in it.

Water level indicator–

Water level indicator is used to indicate the level of water in the boiler. If goes down, it will indicate and thus water level will be maintained by feeding water via a feed pump.

Safety valve–

The safety valve is used to prevent over-steaming inside the boiler. Thus this mounting helps to protect the boiler and its surrounding.

Fusible plug–

It is a secondary safety valve and it works in case of a safety valve failure to protect the boiler from over-steaming and bursting.

Steam stop valve–

This valve is used to collect the saturated steam and send it to the superheater to superheat the saturated steam. This valve is mounted on the top of the boiler shell.

Manhole–

As you know, a manhole is used to clean the boiler from the inside. This is basically a place to go inside if any cleaning or maintenance is needed.

Low water safety valve–

It measures the quantity of water inside the boiler. if goes low, it indicates.

Fire Bridge-

A fire bridge is used to deflect the hot gases coming from the firebox and it prevents the ash particle from going inside the fire tube.

Blow off cock–

The function of a blow-off cock is to remove the water inside when needed.

Economizer–

The function of an economizer is to heat up the water going inside the boiler shell through waste hot gases.

Denser–

This device is used to stop and release the flue gases according to need.

Mountings and Accessories of Lancashire Boiler-

Here are some of the mountings and accesoories of Lancashire boiler-

Mountings:

Safеty Valvе:

Acts likе a guardian. Whеn thе stеam prеssurе bеcomеs too much, thе safеty valvе opеns up to rеlеasе thе еxcеss prеssurе, prеvеnting any potеntial mishaps. It’s likе a safеty nеt for thе boilеr, еnsuring it doеsn’t gеt too strеssеd.

Watеr Lеvеl Indicator:

Kееps an еyе on thе watеr lеvеl insidе thе boilеr. If thе watеr lеvеl drops too low, it signals that thе boilеr nееds morе watеr. Think of it as a watеr watchdog, making surе thе boilеr stays hydratеd.

Prеssurе Gaugе:

Shows how much prеssurе is insidе thе boilеr. It’s likе a prеssurе mеtеr that hеlps opеrators kееp things undеr control. Similar to thе prеssurе gaugе in a car, but for a boilеr.

Accеssoriеs:

Economizеr:

Savеs еnеrgy by using hot fluе gasеs to prеhеat thе watеr bеforе it еntеrs thе boilеr. It’s likе rеcycling hеat. Picturе it as a hеat boostеr, making surе no еnеrgy goеs to wastе.

Suppliеs thе boilеr with watеr. It’s likе thе watеr dеlivеry pеrson, making surе thе boilеr nеvеr goеs thirsty. Think of it as a watеr pump filling up a swimming pool; in this case, thе pool is thе boilеr.

Blowdown Valvе:

Gеts rid of impuritiеs and sludgе from thе boilеr watеr. It’s likе a clеaning crеw еnsuring thе watеr stays purе. Picturе it as a drain for thе boilеr, flushing out thе gunk.

Working of Lancashire Boiler-

Hot gases are generated by burning solid fuel in the firebox of the combustion chamber.

Now, these hot gases flow into the fire tube, when these hot gases flow into fire tubes, they transfer the heat to surrounded water flowing around the fire tubes inside the boiler shell.

The heat exchange happens between the fire tube and surrounded water and this cause generation of steam at the top of the boiler shell.

Now, these hot gases flow outside the fire tube and go to the bottom of the boiler shell where these hot gases are divided into two subways, aiming to heat the surrounded water providing heat from both sides at the bottom surfaces of the boiler.

Then, these hot or flue gases move to the superheater and then economiser to heat up the feed water going inside the boiler to increase the efficiency of the boiler and maximum utilization of hot gases.

And, then these fully consumed hot gases exit from the chimney and superheated steam is taken away for further use.

This is how this boiler works.

This was the construction and working of Lancashire boiler, now let’s move the advantages and disadvantages of Lancashire boiler and its application.

Advantages-

Here are some advantages of Lancashire Boiler-

- Due to three passes of flue gases, the heating surface area per unit volume of the boiler is large.

- The fluctuation in load can be easily met by this boiler due to the large reservoir.

- Easy operation

- low maintenance costs, easy to clean and inspect.

- By use of economiser and superheater, maximum heat of flue gases is utilized, so the efficiency of the boiler can be increased.

- High thermal efficiency

Disadvantages-

Here are some Disadvantages of Lancashire Boiler-

- Maximum working pressure is limited to 16bars

- Due to brickworks, larger space is required

- Slow pressure-building response

- Area restriction due to internally fired chamber

- Leakage

Applications-

Here are some Applications of Lancashire Boiler–

- Sugar mills

- Textile industries

- power generation

- Steam turbines

- Locomotive

- Marines

To further get visual information watch out this animated video of this boiler-

Conclusion-

That’s it for now. I hope you liked the way it presented and gain desired information and thus it added some value to you.

If so, share with your friends and colleagues or needy ones, this will help them to grow. Sharing links are down below, kindly hit your preferred sharing medium from those multiple sharing options.

Want to read more? Here are some suggested articles, you should read further-

Thank you for being with me. I hope to see you in the next session, so don’t forget to bookmark Engineers Rail for further convenient reading.

Here is your gift, which I promise to give at the end of the article. So, here it is-

| Lancashire boiler pdf | |

| Lancashire boiler ppt |  |

FAQs-

Lancashire is a horizontal boiler.

There are two fire tubes in the Lancashire boiler.

Lancashire boiler is a fire tube boiler.

It is a multitube boiler, having two tubes.

It can depend on the requirement. In general, steam generation is 8500kg/hr with a working pressure of 7-20bar.

This boiler has a diameter of 2-3meter with a length or height of 6-10meter.

The diameter of the internal flue tube is 80-100cm of this boiler.

Fire Brick bridge is located at the front of the grate to prevent the flow of coal and ash in the fire tubes and also deflect hot gases upward.

This is used to allow the supply of the water to the boiler at high pressure continuously and to prevent the back flow of water from the boiler when the pump pressure is less than the boiler pressure.

The efficiency of the boiler without accessories can be 65%.

The overall efficiency of this boiler is about 80-85% with mounted accessories.

Safety valve, steam valve, fusible plug, feed check valve, pressure gauge, water level indicator, low water high steam safety valve, blow-off cock.

It is used to control the flow of gases and regulate the combustion rate and steam generation rate.

It is mounted on the top of the main flue tube, just over the grate and it prevents overheating the boiler tubes.

High steam low water safety valve

Abhishek Tiwary is a blogger by passion and a Quality Engineer by profession. He completed his B.Tech degree in the year 2017. Now working in a reputed firm. He loves to share his knowledge with others.