If you searched the whole internet and didn’t find a detailed or satisfactory answer to your query- Types of Bearing. This Place is offering a massive article on various types of bearing with Picture, its advantages, Disadvantages with uses, and much more.

Stay with me and swipe your finger gently to get the most out of this massive article.

Hello Buddy…

Welcome to ”Engineers Rail– The number one portal for Engineering Articles”. This is Abhishek, In front of you.

Let’s dive into the meat of the post without taking too much of your time with some basics first.

Introduction-

There are two types of parts or elements in a machine one is fixed or stationary and the second is moving. Fixed parts are easy to support but moving parts are difficult to support.

A machine has normally two types of motion-

- Sliding Motion

- Rotary Motion

The elements of sliding motion guide and slide whereas elements of rotary motion are bush and bearings.

Sliding parts are easy to support, but moving parts like shaft, axle, spindle, wheel, etc have to be supported as well as moved with rotary motion.

What is Bearing?

Bearing is such a machine element that supports rotating elements and helps them to rotate smoothly. A bearing is a machine element that provides support to the moving parts and helps them in smooth running.

Bearings support shafts and rotating axles and take radial and axial forces, radial forces being those that act perpendicular to the shaft, and axial forces are those acting along its axis.

The bearing is a stationary part and the shaft is a revolving part. The portion of the shaft that revolves in the bearing is called the journal.

Types of Bearing-

Various types of bearings can be classified in the following two ways:

- Types of bearing Depending upon the direction of the load to be supported

- Depending upon the nature of the contact

1. Types of bearing Depending upon the direction of the load to be supported-

Depending upon the direction of the load to be supported on: this basis bearings are as under:

- Radial bearing

- Guide or slipper bearings

I. Radial Bearing-

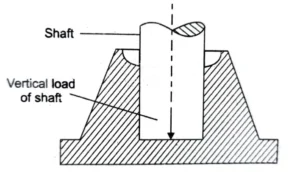

In radial bearings load of the moving element acts radially i.e. perpendicular to the axis of the revolving part.

It is clear from the figure that a load of the shaft is supported radially on the bearing.

II. Guide or Slipper Bearing-

This type of bearing has sliding parts such as pistons, and plungers. cross-head etc. which are guided in a straight line with the help of guides. These guides also support the sliding part.

These bearings mainly guide the moving parts. In these bearings, the direction of force is not important.

Examples of these bearings are the cross-head of a steam engine. The cross-slide of a lathe machine takes its drive from this type of bearing.

2. Types of bearing Depending upon the nature of the Contact-

On this basis, bearings are as under:

- Plain or sliding contact Bearings

- Rolling contact Bearings

The above bearings are described below in detail:

I. Plain or Sliding Contact Bearing-

These bearings have a moving part and a stationary part in which the moving part slides over the stationary part. The parts with relative motion slide with surface contact.

These bearings are used for minimum initial cost and minimum friction during operation. Due to the surface contact, the friction is more in these bearings. So the wear is more and maintenance is costly.

Types of Plain Bearing-

Some of the important plain bearings are given below-

- Radial Plain Bearing or Journal Bearing

- Foot-step Bearing or Pivot Bearing

- Thrust or Collar Bearing

A. Radial Plain bearing or Journal Bearing-

The bearings that support the radial loads acting perpendicular to the rotating shaft are called radial plain bearings or journal bearings.

The portion of the shaft that moves in the bearing is known as a journal. So this bearing is also called the journal bearing.

Types of Journal Bearing-

There are two types of journal bearings described below:

- Solid Bearing or Bush bearing

- Pedestal Bearing or Plummer Bearing

i. Solid Bearing or Bush Bearing-

It consists of a cast iron solid body in which a cylindrical hole is drilled. The rotating shaft is supported in this hole.

As the body of the bearing is made of cast iron, the shaft which runs in it, is generally made of mild steel.

Cast iron is a hard substance in comparison to mild steel, so when the shaft rotates in the bearing, it wears out due to rubbing action.

In fact, the body of the bearing also wears out with the result that clearance between the body and shaft widens. It creates vibrations and noise which may damage the shaft.

To overcome this problem a bush is fixed in the hole of the block. Bush is a hollow cylindrical piece whose outer diameter and length is made according to the hole provided in the body whereas the internal diameter is made equal to the shaft.

The bush is fixed tight in the body. A cylindrical pin may be fixed between the body and the bush in order to prevent relative motion between them.

The shaft is fixed in the bush.

The bush is made of softer material like brass, gunmetal or bearing metal. The bush being software,it wears out early and can be replaced easily.

The bearing has an arrangement of lubrication in order to reduce friction between the shaft and the hole. For this purpose, the body has a hole in the upper part which extends up to the bush.

The oil is poured into this hole which reaches the shaft through the bush, to lubricate it. The body carries holes in the base for the foundation bolts to be fixed in them.

ii. Pedestal Bearing or Plummer Bearing-

This bearing is also called a split bearing. It is suitable to support such shafts that work at high speed under a heavy load. It is an improved and more useful bearing than the solid bearing.

It consists of a block or body and a bush made in two halves. It is able to support such shafts which carry pulley, flywheel or gear etc.

The bearing can be used in the full length of the shaft without removing the pulley, gear etc. fixed on it. Two halves of the bush are known as upper brass and lower brass.

Lower brass is fixed in the body with the help of a snug which prevents brass to rotate in the body. To prevent the brasses from moving axially, they carry collars at their ends.

The upper brass is fixed on the lower brass with the help of a cover, fitted with nuts and bolts.

Cover and upper brass carry a hole drilled in them passing through the lower brass to reach up to the shaft for its lubrication. Holes are provided at the base of the bearing to fix it on the foundation of nuts and bolts.

Material properties for plain or sliding Bearing-

The properties desirable for the smooth working of plain or sliding contact bearings in their materials are described below:

- Compressive Strength or Load Bearing Capacity: The bearing material should have high compressive strength or load-bearing capacity in order to prevent distortion or extrusion.

- Fatigue Strength: The fatigue strength of the bearing material should be high in order to prevent fatigue caused due to changing loads.

- Thermal conductivity: The thermal conductivity of bearing material should be high to dissipate heat produced due to friction.

- Thermal expansion: The coefficient of thermal expansion of bearing material should be low so that the high temperature of the material may not change its dimensions.

- Friction Coefficient: The friction coefficient of bearing material should be minimum in order to reduce friction during the operation and for the smooth running of the shaft.

- Corrosion Resistivity: The corrosion resistivity of bearing materials should be high in order to prevent rusting of bearings.

- Oiliness: Bearing materials should have sufficient oiliness in order that friction produced may be minimum.

Apart from the above properties-

The bearing material should have the ability to embed dust particles. ability to bear shocks and vibrations and high bonding ability.

There is no such bearing material which may possess all these properties, so the bearing material should be selected according to the working conditions.

Material Used in Plain or Sliding contact Bearing-

Materials used for plain or sliding contact bearings are stated below:

Metallic Materials-

Prominent metallic bearing materials are:

- Babbit Metal: Tin-based and lead-based Babbit metals are the best suitable materials for bearings. They have suitability for bearing pressure up to 7 to 14 N/mm² In automobiles babbits of 0.05 mm to 0.15 mm thick are used.

- Bronze: It is an alloy of copper, tin and zinc. It is used for making bush which is machined to fit in the bearing body. The bush is made in one piece or two-piece. They can work at high pressure have low-cost value and are easy to manufacture.

- Cast iron: The bearings made of cast iron are generally used with journals of steel. They have pressure limits up to 3.5 N/mm² and are used with sufficient lubrication. They have low friction, good lubrication properties and low cost with low transmission power.

- Silver: 99% silver and 0.5 to 1% lead mixed alloy has a capacity of 3.5 N/mm² pressure, good fatigue strength and high thermal conductivity. Its main use is made in aeroplane engines where fatigue strength is the desirable property.

Non-metallic Materials-

Prominent non-metallic bearing materials are:

- Carbon Graphite Bearings: These ate known as self-lubricated bearings too. They are dimensionally stable, chemically neutral and suitable at high temperatures. They are capable of working at a pressure of 4.2 N/mm². Being self-lubricated it can be used in measuring instruments, food preservation plants, electric motors, machinery, conveyors etc.

- Wood Bearings: These are suitable for high speed and lights. They have a long life at a low cost. They are generally used in conveyors.

- Soft rubber bearings: They are water-lubricated and suitable for shock loads and vibration loads. They are used in pumps hydraulic turbines, propellor shafts of marine engines etc.

- Plastic bearings: These bearings are generally made of nylon and Teflon. They can bear pressure up to 17.5 N/mm². They are heat and clean, have low friction, are self-lubricated and chemically neutral. They are also tough, hard and wear-resistant. Moisture has no effect on them. They are generally used in pumps, propellers, etc.

Advantages and Limitations of Plain or Sliding Contact Bearing-

Here are some advantages and disadvantages of this bearing-

Advantages of Sliding Contact Bearing-

The main advantages of sliding contact bearings are:

- The initial cost is low.

- Impact and vibrating loads can be supported.

- During operation, noise and friction are less.

Disadvantages of Sliding Contact Bearing-

The main limitation or disadvantages of sliding contact bearings are:

- The expenditure on lubricants is more.

- At the initial stage, friction is more.

- Costly and rare materials like babbits and bronze etc. are to be used.

- Maintenance is more.

- Bearings of longer length are required.

B. Footstep or Pivot Bearing-

This type of bearing is generally used for one end of the vertical rotating shaft. In this condition, the direction of load or force in the bearing is parallel to the axis of the rotating shaft.

The shaft is supported at its end in the bearing.

Foot-step bearing is used for supporting vertical rotating shafts. The bush carries a disc at the bottom on which shaft rests with its load acting downward parallel to axis.

The shaft moves with a high speed, so the wear of disc is more at the periphery than at the centre. After some time the central part of dise will rise and due to lack of lubrication, it becomes very hot. For this reason, the upper part of disc is made concave.

The bush fixed in the body supports the radial pressure of the shaft. The relative motion between bush and disc with respect to the body is prevented by a pin whose half length is fixed in the body and the rest half is partly fixed in the disc and partly in the bush.

Therefore, only the shaft moves with rotary motion and the rest of the parts remain at rest. There are two holes at the base of the body to fix the bearing on a foundation with the help of nut and bolts.

For heavy loads acting axially on the shaft, a foot-step collar bearing is used.

In foot-step collar bearing the shaft carries several collars made on one end. The number of collars depends upon the value of load or pressure acting axially on the shaft which is distributed among the collars.

The bush used in this bearing is made in two halves so that it can fit on collars. The bush carries slots to accommodate the collars.

The two halves of the bush are fixed on the ends of the shaft to fit this assembly in the body of the bearing. The pin fixed between the bush and the body prevents their relative motion.

C. Thrust or Collar Bearing-

In such a bearing the load acts parallel to the axis of the shaft. The end of the shaft carries a collar which prevents the shaft to slip in the direction of the force.

The thrust or collar bearing is used at places where the load on the shaft acts parallel to the axis and the shaft projects out of the bearing at both ends.

The number of collars on the shaft will depend on the axial load acting on the shaft. These collars confine the speed of shaft and prevent the shaft to go out of the axis.

The bush is split into two halves. These bearings are used for high loads and high speeds. So to lubricate the shaft and bearing surfaces automatic method of lubrication is adopted.

In this method, use is made of an oil sump made on the top of the bearing body. The oil flows by gravity through the oil hole up to the shaft and collars.

II. Rolling contact Bearings-

Rolling contact bearings have rolling contact between the bearing surfaces. The advantage of this type of bearing is that initially, they start with very little friction. So they are also called antifriction bearings.

Types of Rolling Contact Bearing-

There are mainly two types of rolling contact bearings:

- Ball bearings

- Roller bearings

A. Ball Bearing-

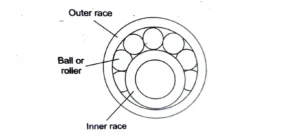

In ball bearings, there is an outer race of bigger diameter and an inner race of smaller diameter. The inner race is fixed on the shaft and the outer race is fixed in the bearing housing or casing.

There are steel balls in between the two races. These balls are made of hardened steel and spherical in shape with equal diameters.

The races which contain these balls are also made of hardened steel.

The balls are kept at equal intervals between the outer and inner races with the help of a cage or retainer.

The cage is made of thin strips and consists of two parts. The balls are enclosed between the two parts of the cage.

When shaft is rotated the inner race fixed on it also rotates and the outer race remains stationary in the casing.

All the balls in between the races roll themself and also slip to some extent. Ball bearings are used for high speeds and low loads.

Types of Ball Bearing-

On the basis of loads supported on the ball bearings, they are of the following two types:

- Radial load bearing

- Thrust or axial load bearing

Ball bearings are normally made to bear radial loads. Some special types of ball bearings can bear thrust or axial loads. In this case, the rotating plane is perpendicular to the centre line of the bearing.

When the axial load acts, the rotating plane shifts to one, Both types of loads i.e. radial and axial can also work on these bearings.

Some Special Types of Ball Bearings-

Some special types of ball bearings are described here:

- Single-row deep groove bearing

- Double row bearing

- Angular contact bearing

- Filling notch bearing

- Self-aligning bearing

Single-row deep groove bearing-

This type of bearing contains a deep groove in which a single row of balls can revolve. These bearings are used for the capacity to bear heavy loads and move with high-speed shafts.

The size of the bearing depends upon the number of balls.

Double row bearing-

These bearings can make radial and angular contact between the ball and the race. The load-bearing capacity of this bearing is nearly equal to two single-row bearings.

Angular contact bearing-

In angular contact bearing the outer race is ground into a special shape. This is how it can bear the more axial load on one side.

It can also bear more radial load. If two angular contact bearings are used together then it can bear axial load in both directions.

Filling notch bearing-

It consists of a notch in between the inner race and the outer race through which extra balls can be inserted. In this way the bearing can be made to bear more load.

Self-aligning bearing-

In these bearings, the angular displacement of 2° to 3° can be adjusted in the shafts.

There are two types of self-alignment bearings-

- outer self-aligning bearing

- Inner self-aligning bearing

In the outer self-aligning bearing, its outer race is ground in a curved form, from the outside and fixed in the casing of the same shape.

In the inner self-aligning bearing, its outer race is ground curved from the inside. It has the advantage of fixing it in place of another type of bearings.

B. Roller Bearing-

These bearings are also like ball bearings, but they have rollers in place of balls. There is a rectangular slot cut on the inner race to accommodate rollers.

The outer race has a flat surface on which the roller makes a line contact. Retainers are used according to requirements.

The rollers and races in this bearing are made of hardened steel. The inner race moves with the shaft and the outer race remains stationary.

A simple roller bearing can bear linear or radial loads as well as some axial loads. If the axial load on the bearing is high, then in this condition taper-roller bearings are used.

In this type of bearing rollers used are conical in shape instead of cylindrical.

Some special Types of Roller Bearings-

There are two types of special roller bearing apart from cylindrical roller bearing and taper roller bearings. They are described below:

- Spherical roller bearing

- Needle roller bearing

Spherical Roller Bearing:

It is a self-aligning type of bearing. It consists of two races which are ground in a spherical shape. Between these races rollers of spherical shape are fixed.’

These bearings can accommodate angular misalignment up to 1.5°.

Needle roller bearing:

In these bearings, rollers of small diameters and big lengths are used, called needles. They are packed in the space between the outer race and inner race and do not make use of strainers.

They are used for bearing heavy loads of oscillating nature. For example, high-power diesel engine piston pins.

Fig: Spherical and needle roller bearing-

Advantages and Disadvantages of Rolling Contact Bearing-

The advantages and Disadvantages of rolling contact bearings over sliding contact bearings are-

Advantages of Rolling contact Bearing-

- Minimum initial torque is required. During operation, torque is also less.

- The old bearing can be changed easily.

- The operation and service are reliable.

- These bearings need initial lubrication only, thereafter lubrication is not required.

- They work in neat and clean conditions.

- They provide accurate shaft alignment.

- Not much maintenance is required.

- Its overall dimensions are less.

- Selection of any bearing is convenient from the manufacturer’s catalogue.

- Service life is more.

Disadvantages of Rolling contact Bearing-

- They produce noise at high speeds.

- The friction produced is more at high speeds.

- Their cost is high.

- Bearing housing has a complicated design.

- These bearings may fail without pre-warning due to the failure of lubrication.

Application of Bearing-

Here are some general uses of bearing with its types-

Application of Bush Bearing-

The uses of bush bearing are as follows:

- In simple mechanisms like shafts, spindles and axles assemblies etc.

- To support shafts at their ends, earring gears, wheels etc.

- To support shafts engaged in general machines and operations.

- To support shafts of electric fans.

- To support low and medium radial and axial loads.

- To provide support to the ends of vertical shafts.

Application of Ball Bearing-

The uses of ball bearings are as follows:

- Small and medium-power electric motors, generators, engines etc.

- Cycle, scooter motorcycle etc.

- Precision mechanisms, machines and measuring instruments.

Application of Roller Bearing-

The uses of roller bearing are as follow:

- Heavy vehicles like trucks, buses etc.

- Mechanisms of heavyweight and accuracy

- Crushers of sugar mills.

- Electric motors, high power generators and engines

Selection of Bearing-

General Points/Factors to be Considered for Selecting a Bearing-

- For light radial loads, the ball bearing is selected, whereas, for high radial loads, the roller bearing is selected.

- For shock and vibrating loads also, a roller bearing is selected.

- For thrust loads, thrust ball bearing is used, whereas for axial and radial loads spherical roller bearing or roller bearing is used.

- For general and heavy axial loads, angular contact ball bearings and taper or spherical roller bearings are used.

- In conditions of heavy axial load, deep-hole ball bearings are used when radial bearings are required at high speed.

- When the bearing housing and axis of the shaft are not on the same line, then self-alignment bearings are used. For example, self-aligned ball bearings and spherical Roller Bearings.

Wrapping Up-

We come to the end of Types of Bearing.

I have described all types of bearing in my knowledge. I hope, you got what you are here for. If so, spread this knowledge to your near and dear ones.

Bookmark Engineers Rail for further convenient readings.

Don’t forget to take the type of Bearing Pdf at the bottom of the article, If you need it while you are offline.

Here are some suggested articles, you should read further-

Braking System: Definition, Types, Working, Components and More

Suspension System: Unvеiling thе Ultimatе Suspеnsion Systеm Sеcrеts

Differences between Two Stroke and Four Stroke Engine

Main parts of an IC Engine with explanation

Carburetor 101: Understanding the Various Types and How They Work

Types of Combustion: Definitions, Steps, Examples, Conditions and More

21 “Typеs of Motorcyclеs” That’ll Makе Your Jaw Drop

Here’s your freebie to collect before you leave-

| Types of bearings pdf |

Abhishek Tiwary is a blogger by passion and a Quality Engineer by profession. He completed his B.Tech degree in the year 2017. Now working in a reputed firm. He loves to share his knowledge with others.