Magnetic Particle Testing uses one or more magnetic fields to locate surface and sub-surface discontinuity in ferromagnetic materials.

Magnetic Particle Inspection(MPI) is one of the NDT methods where magnets are used to detect flaws in ferromagnetic materials.

In this article, you are going to get detailed knowledge about Magnetic particle Inspection(MPI), from basics to advanced in an understandable manner at your fingertip, right in front of you.

So, Stay with me and I will take you on the journey of knowledge. Without further delays, let’s get straight to the mainstream.

What is Magnetic particle inspection(MPI)?

An NDT method that detects flaws in Ferromagnetic particles(Ex. Iron, Nickel, cobalt, and their alloys) through magnetic field lines, is called magnetic particle testing(MPT).

Principle of Magnetic Particle Inspection-

A strong magnetic field is applied to the test object, if there is any discontinuity on the surface of the test object, magnetic particles get stuck inside the flaws due to magnetic leakage.

The flaw can be seen with the help of magnetic particles.

How does Magnetic Particle Testing work?

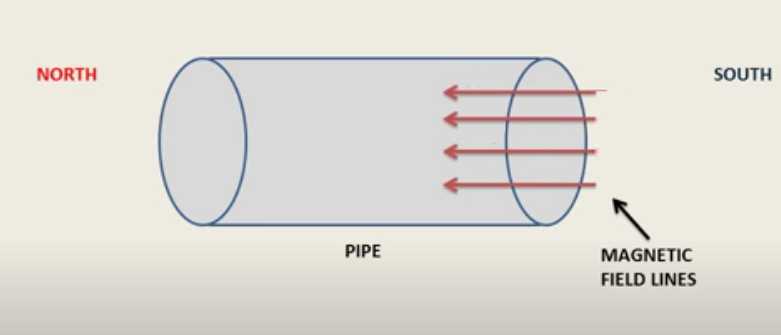

When a test object is placed inside the magnetic poles, it releases a strong magnetic field that magnetizes the whole test object, flowing magnetic lines from one pole to another(ie. north pole to south pole).

If any flaws or discontinuity occur between the magnetic field, magnetic leakage starts to happen, because magnetic lines lose their path in the air.

Then a powder form of magnetic particles is sprinkled on the surface between the magnetic poles. These magnetic particles will get attracted inside the flaw, due to magnetic leakage.

Now, Rest powered will be cleaned and those attracted particles will be left alone. Now, you can easily identify the shape, area, and depth of the discontinuity.

This figure will help you to understand more clearly, Have a look…

Techniques of Magnetic Particle Inspection-

There are mainly two techniques or types of magnetic particle testing used When Magnetic Particle Testing is done. These two methods of MPI are given below-

- Dry Powder Technique

- Wet Technique

1. Dry powder Technique-

The Dry MPI usually chooses to detect flaws on the flat surface. However, it is not advisable for depth inspectors or sub-surface inspections due to the low range of penetration and sticking capacity.

Dry particles can hold temperatures up to 316℃.

2. Wet Technique-

The wet method is mostly and widely used in MPI, due to the flexibility of position selection. The wet technique is suitable for depth penetration and sub-surface discontinuity inspection.

Water-based magnetic particles are advised rather than petroleum-based particles in the wet method due to reduced magnetic permeability.

Methods of Magnetization-

There are two types of methods by which a test object can be magnetized. Those methods are-

- Direct Magnetization

- In-Direct Magnetization

1. Direct Magnetization-

When current passes directly to the test object and gets magnetized through the coil on the object’s surface, known as the direct magnetization method.

2. In-Direct Magnetization-

The magnetic field is induced by using a strong external magnetic field without passing a current through the test object.

The in-direct method can be done by using a permanent magnet or an electromagnet device like a yoke. Known as In-Direct magnetization.

➤ Although a Permanent magnet produces a fixed magnetic field and cannot be increased or decreased according to the need, Electromagnets are preferred use.

An electromagnet gives flexibility in producing magnetic fields.

The procedure of Magnetic Particle Testing-

There are several magnetic particle testing steps that MPI goes through-

- The ferrous material test object is cleaned properly.

- Now, The test object is placed in the MPT test area, If possible.

- The working status of the Electromagnetic yoke is checked through a field indicator(Mostly used Pie gauge)

- After checking the working status, the Yoke is placed between the determined test area.

- A contrast is sprayed on the determined test area to get better contrast and visibility during the inspection.

- Yokes induced the Magnetic flux in the test object.

- The yoke is placed cross-sectionally side by side, maintaining 45 degrees of each move to avoid parallel magnetic field lines in the testing area.

- Now, a wet or dry magnetic particle(Mostly used iron powder) is sprinkled with the help of a blower or container(if, using the wet technique).

- Now, After completing inducing, the excess powder is blown off through a special blower, which blows air in a controlled manner to prevent attracted particles from being blown off.

- Now, the Rest of the magnetic particles stick inside the flaw of the test object due to the magnetic flux leakage.

- Then, According to the shape and formation of particles, an inspection is done.

- As shown in the figure above, the stuck particles indicate an undercut in the weld test piece.

Equipment used in Magnetic Particle Inspection-

- Cleaning Agent- A cleaning agent is used for cleaning the surface of the object.

- Contrast Coating Agent- Contrast coating is used to give the surface a clearer base to see the magnetic particles during the inspection. The mostly white coating agent is used in MPI.

- Field indicator- A field indicator is used to test the workability of an Electromagnetic device(ie. yoke). A pie gauge is also used to test the workability of the EM device.

- Magnetic particles- Magnetic particles are used to attract inside the flaw when magnetic leakage happens in the discontinuity path. Mostly iron powder is used to apply as the magnetic particle. These particles can either be dried or wet.

- Electromagnetic Yoke- Electromagnetic Yoke is used to induce a magnetic field in the test object.

- Blower- A low-pressure blower is used to subside the excess magnetic particles or powder on the surface.

Advantages of Magnetic Particle Inspection-

- Related Article: The Ultimate Guide To Conventional Radiography

Disadvantages of Magnetic Particle Testing-

Limitations of Magnetic Particle Inspection-

Application of Magnetic particle inspection-

Related Article: Leak Testing: A Detailed guide you should never miss

Standards and codes of Magnetic particle inspection-

History of Magnetic Particle Inspection-

In 1868, Ferromagnetic materials were inspected by magnetizing them and passing a magnetic compass over them.

Also, finding magnetic leakage in the magnetized area is the key point to finding flaws in those objects and at that time no magnetic particles or any type of ferrous powder is used.

Conclusion–

Before you go, Here are your freebies all yours-

| Magnetic particle inspection ppt |  |

| Magnetic particle inspection pdf |

FAQs-

Abhishek Tiwary is a blogger by passion and a Quality Engineer by profession. He completed his B.Tech degree in the year 2017. Now working in a reputed firm. He loves to share his knowledge with others.