What is Gray Cast Iron?

Grey cast iron is a form of iron that appears grey due to graphite cracks in the substance. The graphite flake structure that forms during the cooling process from the carbon in the component is what distinguishes grey iron as “grey iron.”

The grey iron’s characteristics will vary based on the elements fused to pour into the mould and the casting procedure utilized.

Applications of Gray Cast Iron

- Gearbox Cases

- Flywheels

- Valves

- Stove Parts

- Internal Combustion Engine Cylinder Blocks

- Linkages

- Pumps

- Hydraulic Components

- Disc Brake Rotors

- Cookware

What is Ductile Cast Iron?

Ductile iron is sometimes known as spherical graphite iron or nodular iron. It is renowned for its elongation, wear resistance, fatigue, and impact resistance. Ductile iron was first patented in 1948, but following a decade of active research, it saw a ninefold growth in usage as an engineering material.

Graphite occurs as spheroids in ductile iron, which gives it some distinctive features. A small quantity of Nodularizer is added to molten iron of the appropriate composition, and certain minor elements are strictly controlled in the base iron to guarantee that graphite spherical formation is not hampered. The application of multiple control processes ensures the trustworthy processing of ductile iron.

Applications of Ductile Cast Iron

- Heavy Machine Tools

- Piston Rings

- Bushing

- High-Pressure Hydraulic Parts

- Cylinder Blocks

- Cinder Blocks

- Manhole Covers

- Industrial Machinery Parts

Gray Cast Iron vs Ductile Cast Iron

Grey cast iron vs ductile cast iron are the two most regularly used varieties of cast iron. Both have distinct features and uses, making them useful for a variety of industrial and technical tasks. Let’s look at the distinctions between gray cast iron vs ductile cast iron based on numerous aspects.

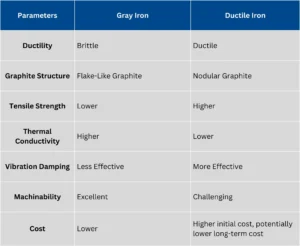

Ductility

When it comes to materials like cast iron, understanding their properties can make a world of difference in engineering and manufacturing.

As its name suggests, grey iron is rigid and brittle. Imagine that sturdy brick wall that has stood the test of time; it won’t budge. Similarly, rather than deforming under stress, grey iron often cracks or fractures. The microstructure of the material, which includes graphite flakes embedded in an iron matrix, is one reason why it is not ductile. The stress concentrator effect of these flakes makes grey iron vulnerable to unexpected failure when subjected to load.

Ductile iron can experience substantial deformation before breaking due to its unusual microstructure, which includes spheroidal or nodular graphite. This graphite structure with its nodules absorbs energy and prevents abrupt failure by acting as an internal shock absorber.

The ductility of grey iron vs. ductile iron may have a big influence on their suitability for different uses. These characteristics are crucial for engineers and manufacturers to think about when choosing a material. Both ductile iron and grey iron have their uses in engineering and industry; the two types of iron are versatile and can handle a wide range of tasks.

Graphic Structure

Grey iron has particles of graphite dispersed throughout the iron matrix. As fault lines, the edges of these flakes increase the material’s susceptibility to breaking. It seems like some weak spots might give way when pressured.

Ductile iron causes the graphite to assume a distinct shape. Instead of flakes, they appear as evenly distributed spherical nodules or spheres inside the matrix. The nodules serve as little shock absorbers, distributing stress more evenly and preventing fractures from beginning and progressing. It maintains the material’s strength and resilience, much as the material’s natural reinforcements.

Tensile Strength

Tensile strength, or the capacity to bear pulling or stretching forces without breaking, is one feature of grey iron vs. ductile iron that stands out in comparison. In many engineering and industrial applications, where the material’s capacity to withstand stress is critical, this distinction is vital.

Grey iron often has a lower tensile strength than ductile iron due to its distinctive flakes of graphite microstructure. The material is more likely to fail under strain because of the stress concentrators that these graphite particles provide.

The spherical graphite nodules found in the ductile iron act as reinforcements within the iron matrix rather than flakes. The material is better able to withstand pulling or stretching forces without breaking because of these nodules, which more uniformly distribute stress throughout the material.

Thermal Conductivity

Grey iron is a heat-transmitting material. This is due to the material’s distinct graphite structure, which resembles tiny pieces all over it. Heat can go through these flakes.

Ductile iron vs. gray iron graphite nodules is more asymmetrical in both form and distribution. Although some heat transmission is still possible via these nodules, it may not be as effective as it is through the flakes in grey iron. It is comparable to a few potholes slowing down vehicles.

The difference in heat conductivity between grey iron vs. ductile iron may not be a deal-breaker in many real-world situations, however. In most situations, ductile iron can still do the same tasks as grey iron, even if the latter may be somewhat superior at transferring heat.

Vibrational Damping

Vibration control is dependent on damping, which consists of absorbing and expelling the disruptive mechanical vibrations that have the potential to cause notable harm to frameworks and machinery. In contrast to ductile iron, grey iron generally exhibits a reduced capacity for vibration attenuation. This is due to the porous graphite microstructure of the material. While these particles can absorb a certain amount of vibrational energy, their release efficiency is comparatively lower, resulting in a more pronounced vibration of the material.

In contrast, the function of ductile iron vs grey iron is to maintain a seamless operation by attenuating vibrations. Its remarkable suspension capabilities are mainly due to the nodular graphite microstructure of ductile iron. Graphite nodules in ductile iron are ovoid, as opposed to particles, and are more effective at dispersing and absorbing vibrational energy.

Machinability

When it comes to moulding and shaping materials, machinability is key. Grey iron is very malleable and easy to shape and form because it includes graphite particles, which function as natural lubricants during production. Brittle graphite also aids in chip creation and removal, which is great for machining.

Due to its denser matrix and nodular graphite structure, ductile iron is more difficult to produce than grey iron. The activity demands more precision and skill to complete, similar to attempting to carve with marble instead of clay. Ductile iron machining was formerly impractical and inefficient, but new cutting tool technologies and machining techniques have made it possible and efficient.

Cost

As an initial consideration, grey iron is the more cost-effective option. For a variety of factors, grey iron is frequently more affordable than ductile iron. To begin with, grey iron production is a relatively straightforward process requiring little energy and fewer steps. In addition, grey iron vs ductile iron frequently requires less expensive acquisition of its necessary basic materials.

Ductile iron vs. grey iron may have a higher initial cost, but believe us when we say it’s worth it. Ductile iron is a viable choice in circumstances where performance and longevity are critical, due to its exceptional mechanical properties and extended operational lifespan.

Conclusion

Now that you know how gray iron vs ductile iron vary from one another, you can choose the best choice for your project. You are well-versed in making situation-specific judgments, such as whether to prioritize the better ductility of ductile iron or the good machinability of grey iron. Mahadev Precision Cast Iron Foundry is a producer of grey and ductile cast iron.

As we part ways, for now, we bid adieu with a promise to be back. Until next time, take care and farewell!

FAQs

What is the difference between grey iron and ductile iron?

Grey iron is tougher and more brittle than ductile iron. However, in many cases, its brittleness has little consequence. Furthermore, it has superior vibration damping and machinability and is less expensive to manufacture.

Which is the strongest: Gray Iron vs Ductile Iron

Ductile iron is usually twice as strong as many gray cast irons, and almost as strong as steel. Ductile iron has many of the same benefits as cast iron, but it is more difficult to cast and shrinks at a different pace. Due to this disparity, distinct patterns are necessary.

When should I use ductile iron?

It’s designed to withstand damage during transportation. Once built, ductile pipe is designed to survive harsh operating circumstances such as river crossings, unstable soils, high water table traffic, deep excavations, and frozen ground. So, in such scenarios, ductile iron vs gray iron would be more useful.

When should I use grey iron?

Grey cast iron can reduce vibrations, making it an ideal material for housing or industrial uses such as equipment bases. Grey iron has excellent thermal conductivity, which allows heat to pass more freely through the metal.

What lowers the ductility of grey cast iron?

Large graphite flakes diminish strength and ductility, therefore inoculants are employed to encourage finer particles. Grey cast iron derives its name from the appearance of its fractured surface, known as “grey,” which is caused by the deflection of graphitic flakes when a crack passes through the material. This deflection leads to the initiation of multiple additional cracks during the process of fracture.

Abhishek Tiwary is a blogger by passion and a Quality Engineer by profession. He completed his B.Tech degree in the year 2017. Now working in a reputed firm. He loves to share his knowledge with others.

![Difference between Orificemeter and Venturimeter [With PDF] Difference between Orificemeter and Venturimeter [With PDF]](https://www.engineersrail.com/wp-content/uploads/2021/09/difference-between-orificemeter-and-venturimeter-150x150.webp)